who we are.

Stainless Steel Manufacturing

Established on the Border in 1996, we’re trusted by both commercial and industrial clients, nation-wide.

Setting the benchmark in quality, innovative design, and reliability, we’re building a legacy of sustainable and socially responsible business practices.

1996

Established In

Engineering for the Generations

Building today to transform

tomorrow

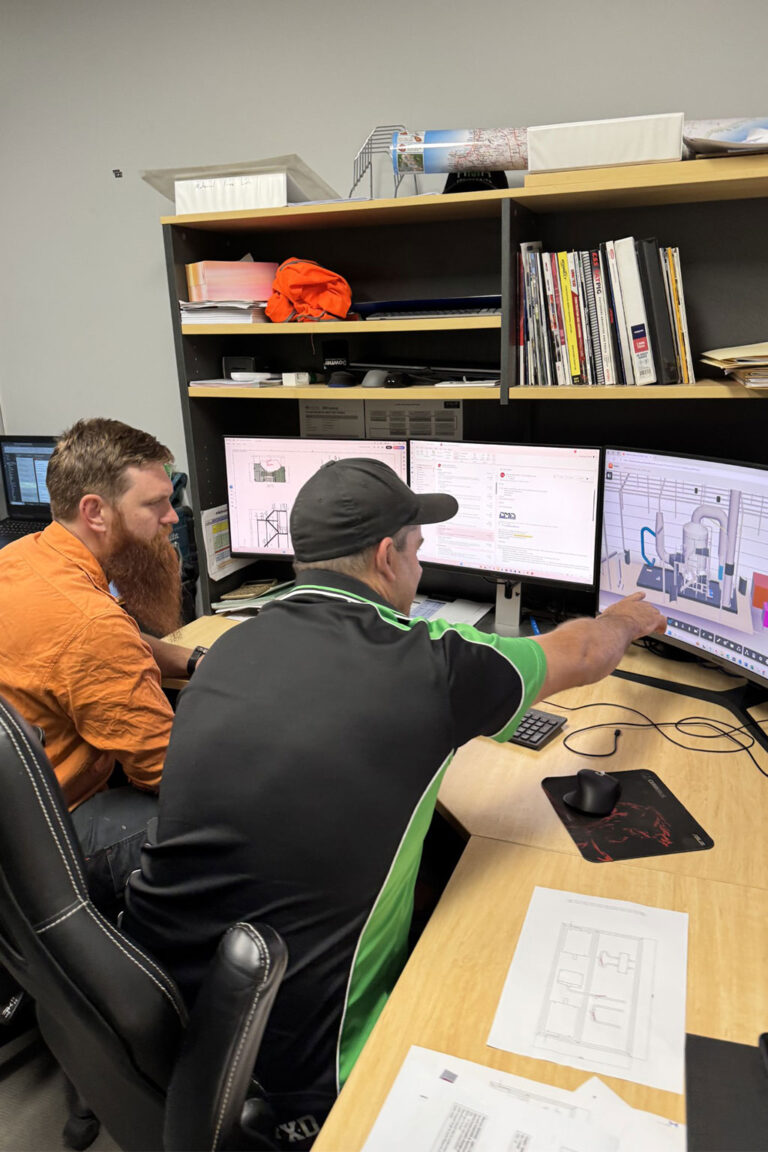

Our clients trust us to manage and deliver engineering projects of the highest quality – it’s what we’ve built our reputation on.

- Innovative Design

- Fabrication

- Installation

- ISO 9001 Quality

RMR Core Focus

- Our purpose is engineering for the generations

- Our cause is helping bridge the Australian skills gap

- Our passion is helping drought-proof the Australian food bowl

- Our industry is engineering, and we want to help shift the engineering industry into a new era

featured projects

from our blog.

RMR Blog

meet our team.

Our experienced experts

After starting his career as an Apprentice Boilermaker in Wodonga, Peter honed his skills in Bathurst, New Zealand and the UK, before returning to Australia. He worked his way up from Site Supervisor and Project Supervisor roles to a Contract Projects Manager with Nestlé for over a decade. Since 2012, when he purchased RMR Engineering, Peter has been at the helm of the business, putting over 30 years of extensive industry experience in Sales, Marketing, Business, Project Engineering and Project Management to good use.

With extensive experience of methods, materials and advanced manufacturing technology and robotics, Phil is tasked with transitioning RMR from an owner managed SME into a diversified medium sized entity, with operations throughout Australia. This will be achieved through the application of systems, standardisation and targeted investment in advanced manufacturing technology.

With an exceptionally strong industry and trade background, Craig has almost 30 years’ experience as a Fitter / Machinist / Welder, with almost 25 of those years spent with us at RMR Engineering. Starting his RMR career in Trade, Leadership and Management roles, Craig has progressed through the ranks to his current role as Projects Manager / Estimator.

Neil has a strong trade background, as a Fitter / Machinist / Welder with over 25-years industry experience, progressing to his current role of Manufacturing Supervisor / HSEQ Representative. Neil joined the RMR Engineering Team in early 2013 and is a vital member of our team.

After starting his career as an Apprentice Boilermaker in Wodonga, Peter honed his skills in Bathurst, New Zealand and the UK, before returning to Australia. He worked his way up from Site Supervisor and Project Supervisor roles to a Contract Projects Manager with Nestlé for over a decade. Since 2012, when he purchased RMR Engineering, Peter has been at the helm of the business, putting over 30 years of extensive industry experience in Sales, Marketing, Business, Project Engineering and Project Management to good use.

With extensive experience of methods, materials and advanced manufacturing technology and robotics, Phil is tasked with transitioning RMR from an owner managed SME into a diversified medium sized entity, with operations throughout Australia. This will be achieved through the application of systems, standardisation and targeted investment in advanced manufacturing technology.

With an exceptionally strong industry and trade background, Craig has almost 30 years’ experience as a Fitter / Machinist / Welder, with almost 25 of those years spent with us at RMR Engineering. Starting his RMR career in Trade, Leadership and Management roles, Craig has progressed through the ranks to his current role as Projects Manager / Estimator.

Neil has a strong trade background, as a Fitter / Machinist / Welder with over 25-years industry experience, progressing to his current role of Manufacturing Supervisor / HSEQ Representative. Neil joined the RMR Engineering Team in early 2013 and is a vital member of our team.

our impact.

by the numbers

Locations Australia Wide

years of engineering excellence

project completed and counting

contact.